|

ML-360

UNIVERSAL AND HIGHLY PRECISE MACHINING

Developed under highly sophisticated production techniques, ML-360 ensures remarkable capability comparable with standard lathes. Versatile machining is facilitated with the comprehensive range of accessories.

ML-360

- SUPERBLY RIGID BED WITH PRECISION GROUND VEE WAYS

- The well located cross bracing and heat treated bed ensures excellent long term rigidity.

- MAIN SPINDLE FOR PRECISE MACHINING

- The hardened and accurately finished main spindle is supported with precision taper roller bearings. Thus steady and long lasting accuracy secured.

- CARRIAGE OF GENEROUS TRAVEL

- The 85mm cross feed ensures adequate range for both lathe work and milling.

- POWERFUL 300 WATT MOTOR FOR FORWARD REVERSE ROTATION

- The change of direction is easily achieved on this powerful condenser motor proving convenient for automatic feed and thread cutting.

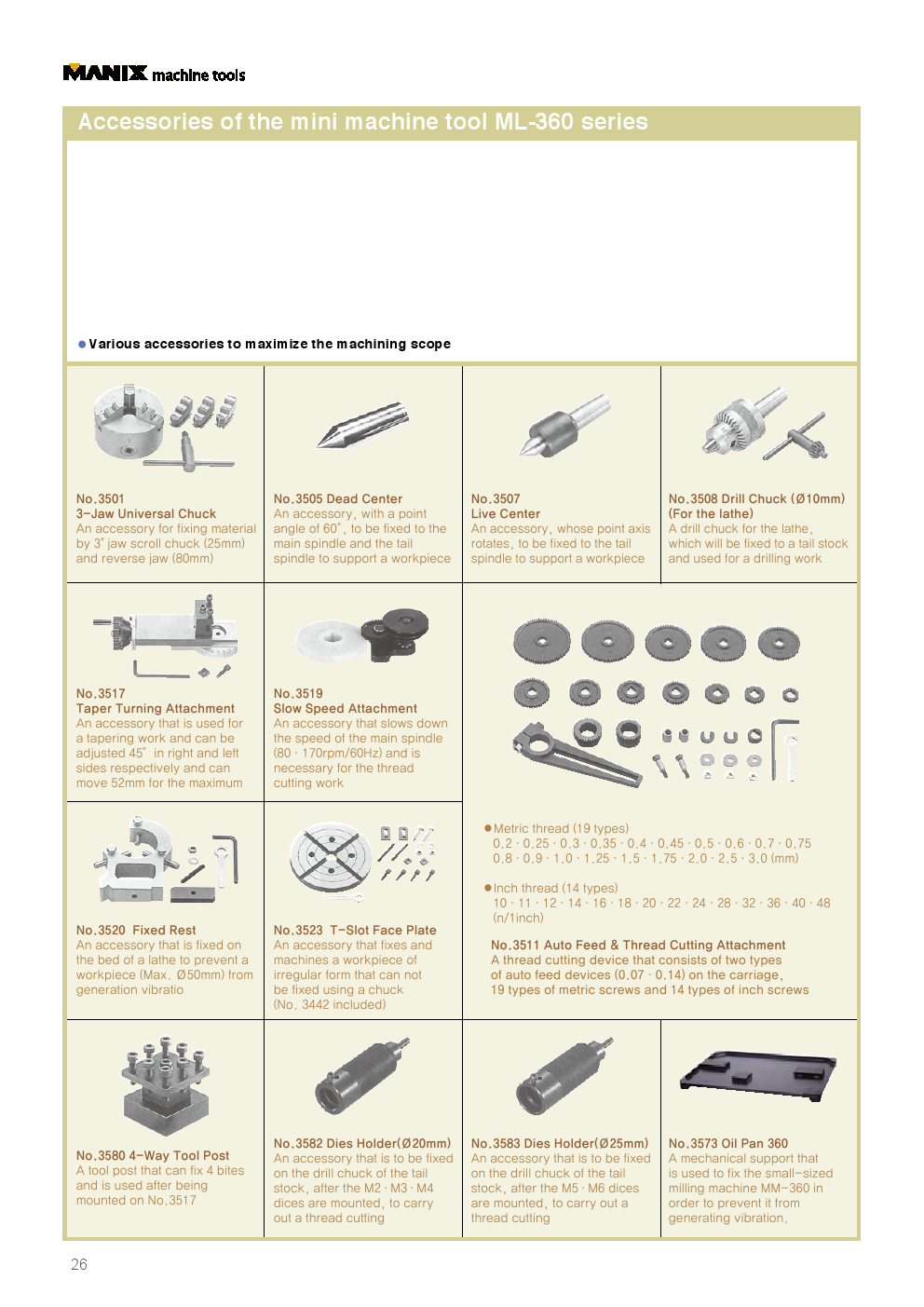

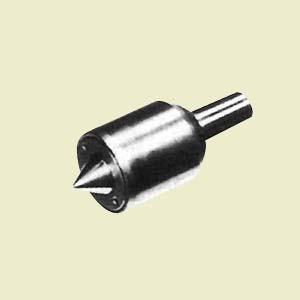

- VERSATILE TAIL STOCK

- Dead or Live center fitted in the tail spindle facilitates turning on long workpiece. Drilling, reaming and so on are also practicable with Drill chuck.

- CONVENIENT 0 (ZERO) – SETTING

- Feed handles are of coaxial ring construction which permits 0-setting operation. Cut depth can be preset and checked easily.

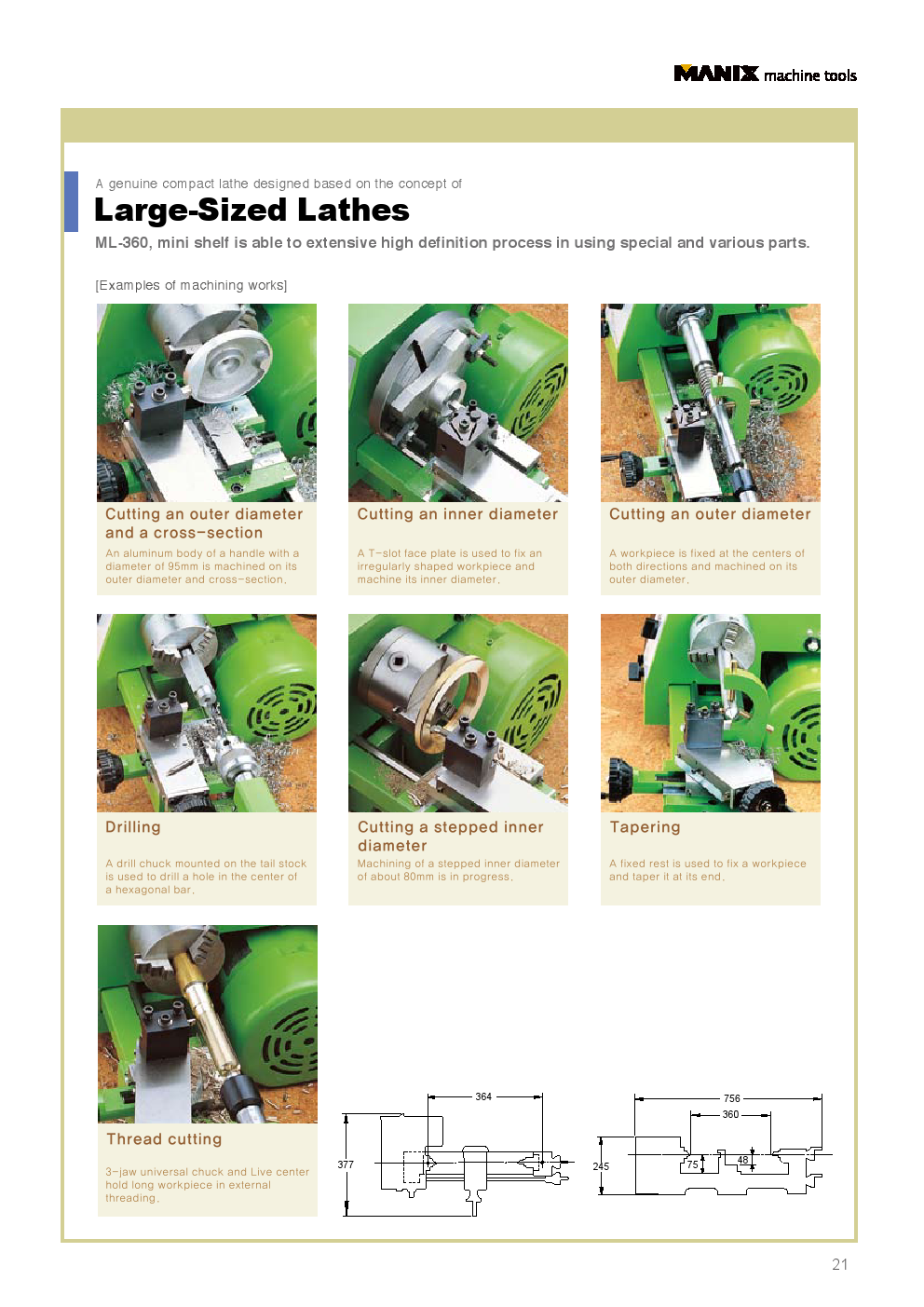

- Cylindrical turning & counter facing: Turning on aluminum workpiece clamped with 3-jaw universal chuck.

- Boring: Irregular shaped aluminum casting in clamped on T-slot face with Fixture.

- Turning between centers: Cylindrical turning between centers. Workpiece is held with Face plate, Lathe dog, Live center and Travelling rest.

- Drilling: Centering and drilling on hexagonal bar performed with Drill chuck fitted in tail spindle.

- Step boring: Workpiece of large diameter is clamped in 3-jaw universal chuck with jaws reversed.

- Taper turning: Turning on the end of long workpiece supported with Fixed rest.

- Threading: 3-jaw universal chuck and Live center hold long workpiece in external threading.

- Wipe the main spindle and 3-jaw chuck with dry clothe before attaching.

2 Fix the 3-jaw chuck tightly by the hexagon bolt.

3 Turn the #1 Taper turning attachment to move the table to the arrow direction.

4 Slightly unfasten #1 two bolts by hexagonal wrench.

5 Turn the taper turning attachment about 30˚ to the arrow direction. Angle gradation is marked.

6 Move the table to the arrow direction to the original position. You can set the angle of taper turning attachment to your required angle. Normally, set up like shown in the picture is convenient in many cases.

7 Turn the tail stock handle to pull out the #1 tail spindle about 5mm to the arrow direction as shown in the picture.

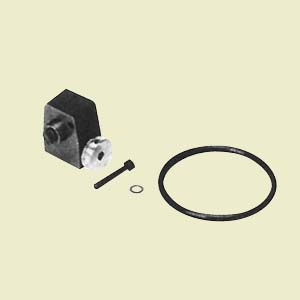

8. Fix the #1 Dead center(No.3507) on the tail spindle to the arrow direction as shown in the picture. Try to feel like hammering in instead of pushing in.

9. When it’s attached like shown in the picture, try to pull out turning center by hand to see if it’s steadily fixed. Turn the handle to the opposite direction and insert the tail spindle completely, turning center automatically comes out.

10.Turn the handle to relocate the tail stock to arrow directions. You must turn the handle to tighten the tail stock after relocating.

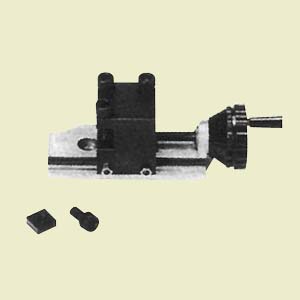

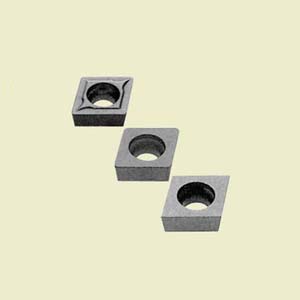

11. Unfasten the bolt by the wrench included in the bit holder.

12. Attach the insert tip as shown in the picture.

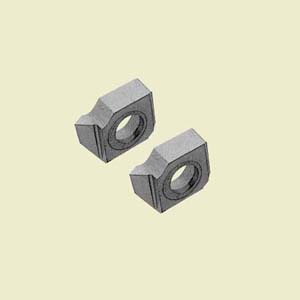

13. Put the #1 right height of a metal piece on the tool post as shown in the picture.

14. Put the bit on top of it, move the tail stock near the tool post and check if the dead center’s end has same high as the end of insert tip. Use different thicknesses of metal pieces to adjust the height of dead center’s end and the end of insert tip most accurately, and fasten it with #1 bolt.

“The center of the tail spindle is manufactured to be accurately same height as the center of carriage on the lathe. Above process is to adjust the height of insert tip and the end of the dead center for the best operating results.”

- You can use the #1 Chuck handle to open and close the #2 jaw of 3-jaw chuck. Insert the material tightly in the 3-jaw chuck.

- Try to move the material by hand to check if it is tightly fastened. If it is loose, try to fasten it again to avoid falling out during process.

- When you separate the jaws from 3-jaw chuck, you can see 1, 2 and 3 numbers on them as in the picture. This is the order for you to install the jaws. One 3-jaw chuck includes one set of correct jaws and one set of reverse jaws. You can use a set of jaws by correct way (max. 25mm) and reverse way (max. 80mm).

- Turn the #1 handle to move the tool post vertically (to Y axis). The smallest gradation is 0.025mm. So if you turn 4 small gradations (one big gradation), it will move 0.1mm vertically.

- Turn the #2 handle to move the carriage horizontally (to X axis). The smallest gradation is 0.025mm as well.

- Turn the #1 power switch to the arrow direction to turn the main spindle. Use the X axis handle and Y axis handle for the cutting process.

- If you unfasten the #1 cover bolt, you can open the cover like shown in the picture and see the inside of speed change gears. You can see the main spindle speed marked inside of the cover according to the belt attachment.

- Unfasten the #1 Tension fix bolt to move #2 Tension pulley to the arrow directions. Unfasten the tension pulley and move the position of the belt to adjust the main spindle speed.

- You can adjust the speed within 6 levels. Please refer to the machine’s specifications for every level’s speed.

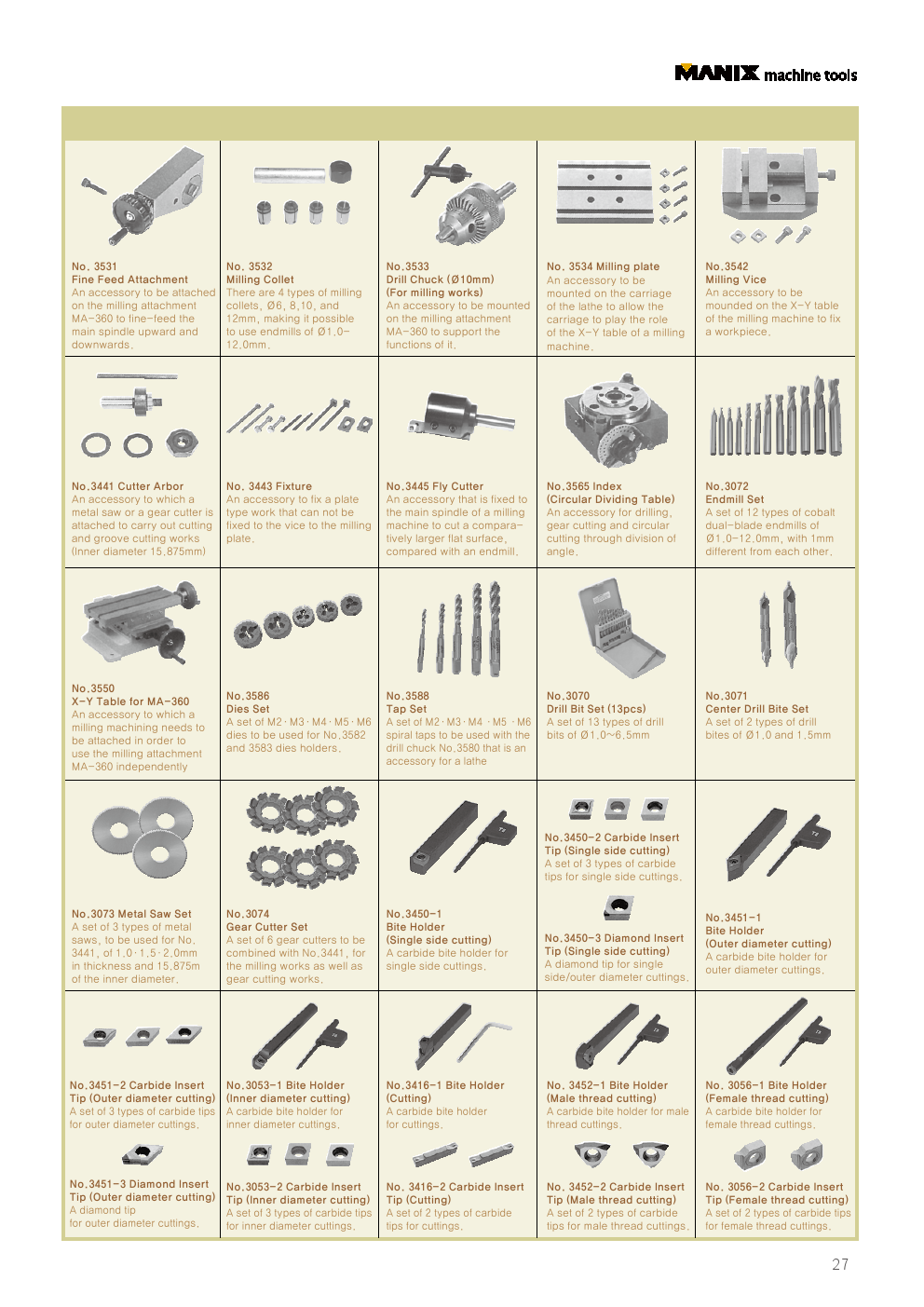

|

Height of the center

|

75mm

|

|

Distance between centers

|

360mm

|

|

Swing over carriage

|

Ø96mm

|

|

Swing over bed

|

Ø150mm

|

|

Main spindle hole

|

Ø16mm

|

|

Main spindle speed

|

260ㆍ520ㆍ845ㆍ970ㆍ1845ㆍ2860rpm(60Hz)

230ㆍ450ㆍ740ㆍ850ㆍ1630ㆍ2520rpm(50Hz)

V-belt 6 level speed changes

|

|

Main spindle taper

|

MT#2

|

|

Tail spindle travel

|

45mm

|

|

Tail spindle diameter

|

Ø24mm

|

|

Tail spindle taper

|

MT#2

|

|

Carriage cross travel

|

85mm

|

|

Carriage longitudinal travel

|

360mm(All over bed)

|

|

Motor

|

Condenser Motor

Single phase 220V Input 470W Output 300W

2600rpm(50Hz)

3180rpm(60Hz)

|

|

Dimensions

|

756 x 377 x 245mm

|

|

Weight

|

30kg

|

|

Máy gia công CNC

Máy gia công CNC

Máy cắt dây / Máy xung

Máy cắt dây / Máy xung

Máy tiện vạn năng

Máy tiện vạn năng

Máy phay vạn năng

Máy phay vạn năng

Máy tiện, máy phay mini

Máy tiện, máy phay mini

Máy gia công tôn

Máy gia công tôn

Máy cắt CNC

Máy cắt CNC

Máy cơ khí khác

Máy cơ khí khác

Phụ kiện gá kẹp Hàn Quốc

Phụ kiện gá kẹp Hàn Quốc

Thiết bị đo, hiệu chuẩn

Thiết bị đo, hiệu chuẩn

Dụng cụ cắt gọt

Dụng cụ cắt gọt

Dụng cụ đo Insize

Dụng cụ đo Insize

Dụng cụ đo Mitutoyo

Dụng cụ đo Mitutoyo

Dụng cụ Vertex

Dụng cụ Vertex

Dụng cụ cầm tay

Dụng cụ cầm tay

Thiết bị hàn cắt

Thiết bị hàn cắt

Thiết bị dạy nghề

Thiết bị dạy nghề

Phụ kiện VERTEX

Phụ kiện VERTEX

Dịch vụ

Dịch vụ

.jpg)