-

Máy gia công CNC

Máy gia công CNC

-

Máy cắt dây / Máy xung

Máy cắt dây / Máy xung

-

Máy tiện vạn năng

Máy tiện vạn năng

-

Máy phay vạn năng

Máy phay vạn năng

-

Máy tiện, máy phay mini

Máy tiện, máy phay mini

-

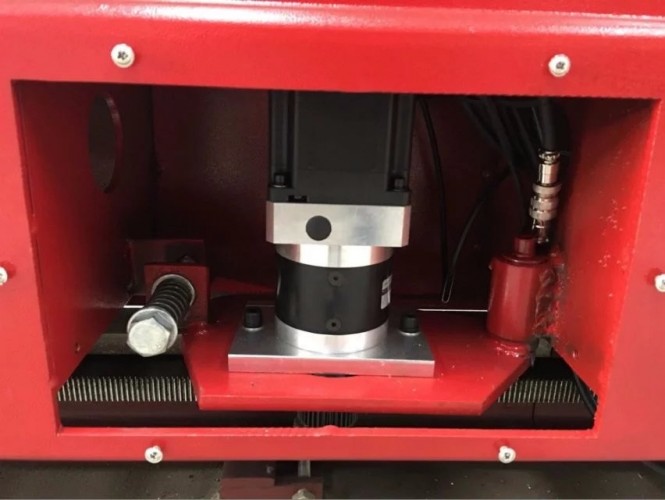

Máy gia công tôn

Máy gia công tôn

-

Máy cắt CNC

Máy cắt CNC

-

Máy cơ khí khác

Máy cơ khí khác

-

Phụ kiện gá kẹp Hàn Quốc

Phụ kiện gá kẹp Hàn Quốc

-

Thiết bị đo, hiệu chuẩn

Thiết bị đo, hiệu chuẩn

-

Dụng cụ cắt gọt

Dụng cụ cắt gọt

-

Dụng cụ đo Insize

Dụng cụ đo Insize

-

Dụng cụ đo Mitutoyo

Dụng cụ đo Mitutoyo

-

Dụng cụ Vertex

Dụng cụ Vertex

-

Dụng cụ cầm tay

Dụng cụ cầm tay

-

Thiết bị hàn cắt

Thiết bị hàn cắt

-

Thiết bị dạy nghề

Thiết bị dạy nghề

-

Phụ kiện VERTEX

Phụ kiện VERTEX

-

Dịch vụ

Dịch vụ

May CNC, Trung tam gia cong CNC, May phay, May tien, May bao, May mai, May khoan, May tien Dai Loan, May tien Han Quoc, may phay Nhat Ban, May phay Dai Loan, May phay Han Quoc, Lathe Machine, Milling machine, CNC Machine.

May phay van nang, May phay giuong, May phay dung, May phay ngang, May phay tru, May phay hon hop, May tien Chau au, May phay Trung Quoc, May tien trung Quoc, May cat ton, May chan ton, May khoan, May mai 2 da, May mai phang, May khoan can, May bua, May mai mui khoan, May phay CNC, May tien CNC, May phay CNC Nhat Ban, May phay CNC Han Quoc, May phay CNC Dai Loan, May CNC Nhat Ban, May CNC Han Quoc, May CNC dai Loan, shearing mahchine.

May han, May han ho quang, May han MMA, May han TIG, May han MIG, May han MAG, May han diem, May han duoi lop thuoc, May cat Plasma, May cat tia nuoc, may cat Laser, May cat fiber, Dung cu do Mitutoyo, Mitutoyo, Thuoc cap, Panme, ban map, ban nguoi, Thuoc do cao, Thuoc do do day, thuoc do khe ho, Dung cu Vertex, E to Vertex, Bau cap mui khoan, collet.

Copyright 2016 © Bami.,JSC