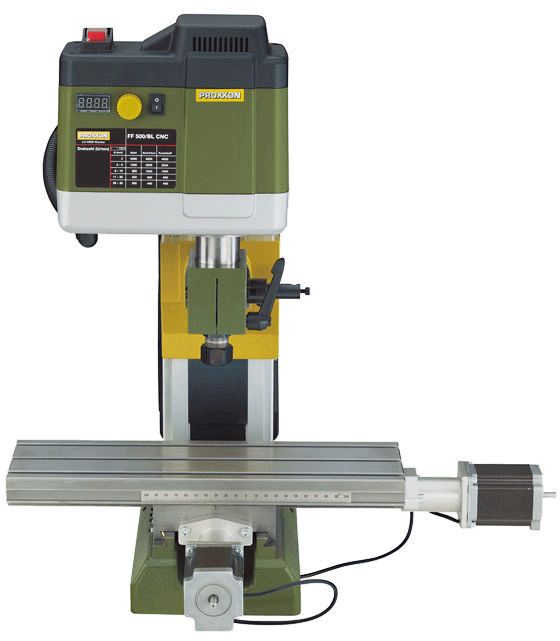

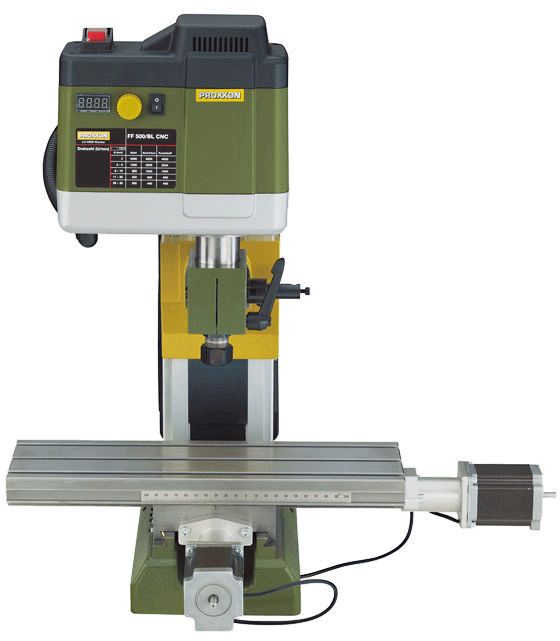

Miller FF 500/BL-CNC-read

With recirculating ball spindles and powerful step motors at all 3 axes.

Interesting for users who already own a control unit or would like to purchase one from another provider on the market.

Three standard plugs (SUB-D 9POLE) are available to connect the control unit. The mechanical construction of the miller is identical to the miller FF 500/BL-CNC.

NO 24 364

Accessories for Miller FF 500/BL-CNC-ready

Dividing attachment UT 400/CNC

4th axis to the PROXXON Miller FF 500/CNC. For perfect 3D processing! For individual parts and small series production. For manufacturing divisions, gear wheels, helical gearings, screw spindles and (including irregular) profiles. All angle positions can be approached by computer control. Easy horizontal and vertical construction. Driven by powerful step motor (2.0A) through toothed belts, and virtually free from play, adjustable worm gear. The high transfer ratio (40:1) provides enormous torque. Main spindle with 14mm drill hole and flange to suit face plates and all lathe chucks from the PD 400 lathe system. Smallest increment 0.003°. Recognition of reference position through light barrier.

Chuck and work pieces are not included in the package.

NO 24 423

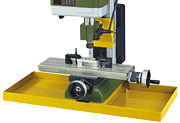

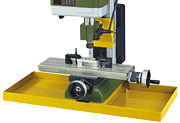

Splash guard and chip collecting tray for PROXXON milling machines

Made of 1.5mm thick sheet steel, powder-coated. Secure stand due to drill holes for fastening to a work surface (the use of steel sleeves keeps the tray tightly sealed). L 700mm, W 420mm, H 40mm.

Suitable for FF 230, FF 400, FF 500, FF 500/CNC, FF 500 - ready for CNC, FF 500/BL, FF 500/BL-CNC and FF 500/BL-CNC-ready as well as for mill/drill unit BFB 2000 and compound table KT 150.

Note: The milling machine depicted here is not included.

NO 24 322

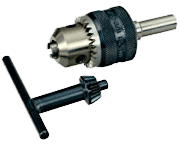

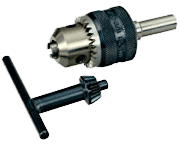

Gear tooth chuck (10mm). With adapter.

Industrial quality, however not as accurate as the collets. With 10mm adapter which fits into the 10mm collet. Includes the chuck key.

NO 24 110

Multiple range standard type ER 20 collets (DIN 6499-B) (not depicted)

For the mill/drill PF 400 (from production no. 401-10910) and miller FF 500 (from production no. 5648). High concentricity and repeat accuracy. May be reduced to 0.5mm under their nominal diameter (intermediate sizes not required). D = 21mm, L = 31.5mm. One each of 2.4 - 3 - 3.2 - 4 and 5mm are included. Supplied in wooden box with sliding lid.

NO 24 253

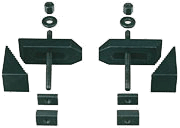

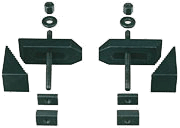

Step clamp set of steel.

2 step blocks and clamps each.

With matching slot nuts and fastening screws for T-slots as per MICROMOT standard (12 x 6 x 5mm). In wooden box with sliding lid.

NO 24 256 For work pieces up to 20mm thickness

NO 24 257 For work pieces up to 35mm thickness

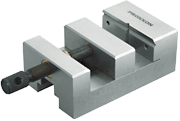

Precision vice PM 60

Perfectly rectangular. To be placed sideways and on the end face. With matching nuts and screws for fixation in MICROMOT standard T-slots (12 x 6 x 5mm). Supplied in wooden box with sliding lid. Jaw width 60mm. Clamping capacity 42mm. Total length 100mm.

NO 24 255

MICROMOT adapter

For use with high-speed MICROMOT rotary tools in combination with the millers FF 500/BL and FF 500/BL-CNC.

The standard milling head is exchanged for the adapter in just a few steps. Our 20mm collar enables to fasten all appliances of the MICROMOT 50 series, the MICROMOT precision drill/grinder FBS 240/E and the MICROMOT professional drill/grinder IBS/E. Especially for applications that require high speeds for small milling cutters (e.g. milling electronic boards), but also for micro drilling. Complete with fastening screws.

The professional drill/grinder IBS/E depicted here is not included.

NO 24 346

Precision V-blocks

Used to clamp various work pieces. Made from hardened steel, precision ground in pairs. Four different depths of prism incisions V, all at 90°. Size 50 x 30 x 30mm. The solid clamp and knurled knob ensure superb securing of the workpiece. Supplied in a wooden box with sliding lid.

NO 24 2622 pieces

Three piece centre drill set

Made of HSS steel. DIN 333 (type A) 60°. Complete set centre drills with sizes of 2 - 2.5 and 3.15mm.

NO 24 630

Milling cutter set (2 - 5mm)

All cutters with 6mm shaft. Cutters of Ø 2 - 3 - 4 and 5mm. Double fluted according to DIN 327. Made of HSS. Comes in wooden box with sliding lid.

NO 24 610

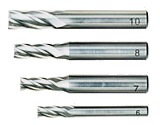

Milling cutter set (6 - 10mm)

4 cutters Ø 6 - 7 - 8 and 10mm. Four flute design according to DIN 844. Shafts 6 and 10mm respectively. Made of HSS. Comes in wooden box with sliding lid.

NO 24 620

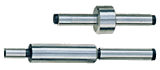

Edge finder set

Used for fast and accurate location of starting point of work pieces with respect to the machine spindle on milling machines. Size 6 x 6 x 50mm and 6 x 5 x 75mm. Comes in wooden box with sliding lid.

NO 24 434

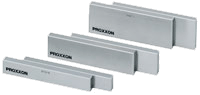

14-piece parallel supports set

For adjusting work on drilling machines, lathes and milling machines. Made of high-alloy, hardened steel (58 - 62 HRC). Parallel accuracy 0.002mm. 2 each of 8 x 10, 15, 20, 25, 30, 35 and 40mm. Length 100mm. Packed in a wooden box.

NO 24 266

Máy gia công CNC

Máy gia công CNC

Máy cắt dây / Máy xung

Máy cắt dây / Máy xung

Máy tiện vạn năng

Máy tiện vạn năng

Máy phay vạn năng

Máy phay vạn năng

Máy tiện, máy phay mini

Máy tiện, máy phay mini

Máy gia công tôn

Máy gia công tôn

Máy cắt CNC

Máy cắt CNC

Máy cơ khí khác

Máy cơ khí khác

Phụ kiện gá kẹp Hàn Quốc

Phụ kiện gá kẹp Hàn Quốc

Thiết bị đo, hiệu chuẩn

Thiết bị đo, hiệu chuẩn

Dụng cụ cắt gọt

Dụng cụ cắt gọt

Dụng cụ đo Insize

Dụng cụ đo Insize

Dụng cụ đo Mitutoyo

Dụng cụ đo Mitutoyo

Dụng cụ Vertex

Dụng cụ Vertex

Dụng cụ cầm tay

Dụng cụ cầm tay

Thiết bị hàn cắt

Thiết bị hàn cắt

Thiết bị dạy nghề

Thiết bị dạy nghề

Phụ kiện VERTEX

Phụ kiện VERTEX

Dịch vụ

Dịch vụ